Guide to Excavators

Excavators are versatile and essential machines for a variety of industries including construction, mining, and agriculture. This excavator guide will provide an in-depth look at excavators and their types, sizes, specifications, attachments, applications, and major brands to help you make an informed decision when choosing the right excavator for your needs.

The Importance of Excavators in Various Industries

Excavators play a crucial role in several industries by enhancing productivity and efficiency. They are used for tasks ranging from digging foundations and moving earth to demolishing structures and extracting resources. Understanding the importance of excavators can help you leverage their capabilities effectively in your projects.

What is an Excavator?

An excavator is a heavy construction machine designed for digging, lifting, and moving materials. It typically features a boom, arm, bucket, and cab, mounted on a rotating platform called a house. Excavators are used for a wide range of tasks, including excavation, grading, and demolition.

What Type of Excavator?

There are many types of excavators, each suited for different projects. This guide will introduce you to the most common types of excavators on the market.

1. Crawler Excavators

Crawler excavators are the most popular type among all excavators. They are versatile machines typically made up of tracks, a boom, a stick, a bucket, and a cab. They are widely used in various fields such as construction, mining, agriculture, and earthmoving.

2. Wheeled Excavators

The main difference between wheeled excavators and crawler excavators is that wheeled excavators run on wheels instead of tracks. This feature makes them easier to move, allowing them to travel between job sites independently, reducing the need for transportation and cutting down project costs. In an urgent project, wheeled excavators can quickly reach the site

3. Long-Reach Excavators

Long-arm excavators have an extended arm and boom, giving them a greater reach. This design is advantageous for projects like high-rise demolition or digging deep trenches, where a regular arm cannot reach.

5. Backhoe Excavators

Backhoe excavators combine the functions of an excavator and a loader into one machine, making them suitable for various projects. The front part is equipped with a large bucket or blade, similar to a loader, for pushing or leveling land. The rear part, like a crawler excavator, has an arm, but it can only rotate 205 degrees and cannot make a full circle.

5. Demolition Excavators

Demolition excavators are known for efficiently demolishing dangerous buildings. They offer high performance and fuel efficiency, making them ideal for these tasks.

Excavator Sizes

Excavators can be classified not only by type but also by size.

1. Mini Excavators

Mini excavators typically weigh under 7 tons. Their lightweight design makes them ideal for digging in tight spaces and handling small construction projects. Mini excavators are also more affordable, so if you’re on a budget and working on a smaller project, a mini excavator might be a good choice. However, keep in mind that mini excavators have less power and can’t handle heavy-duty tasks.

2. Medium Excavators

Medium excavators usually weigh between 7 to 40 tons and are the most common type on the market. They offer more power than mini excavators and can dig as deep as larger machines, while still being lighter in weight. This makes medium excavators widely used in commercial construction projects.

3. Large Excavators

Large excavators typically weigh over 45 tons and are considered heavy machinery. They are suitable for large-scale projects, such as demolishing buildings or digging foundations for skyscrapers. However, transporting them can be challenging due to their large size, so it’s important to plan accordingly when choosing a large excavator.

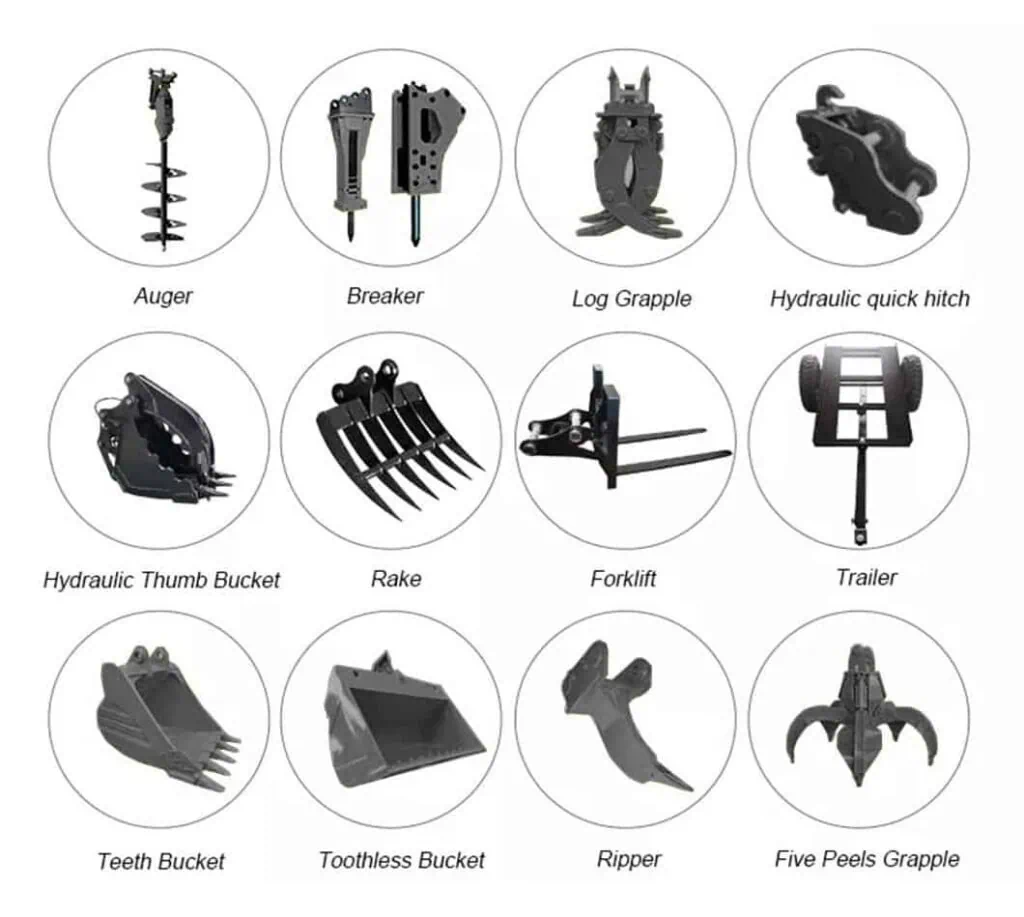

Common Attachments for an Excavator

Excavator attachments are various tools that can be installed on an excavator. Here are some common attachments and their uses:

1. Bucket

The bucket is the most common excavator attachment, used for digging, moving, and loading soil and other materials.

2. Hydraulic Breaker

A hydraulic breaker is used for demolishing concrete, rock, or other hard materials.

3. Hydraulic Shear

Hydraulic shears are mainly used for cutting steel, metal pipes, and rebar.

4. Auger

An auger is used for drilling holes, especially for installing utility poles, signs, or trees.

5. tiltrotator

A tilt rotator allows excavator attachments to rotate and tilt in multiple directions, making operations more flexible and precise.

6. Hydraulic Grapple

A hydraulic grapple is used for grabbing, moving, and loading various bulk materials like scrap metal, wood, and waste.

Applications of Excavators

Excavators play a crucial role in many fields and are widely used in construction, mining, public works, agriculture, and forestry.

In construction, excavators are great helpers for digging foundations and earthworks, efficiently laying a strong foundation for projects. In mining and quarries, excavators lead the way in resource extraction and also handle transportation, ensuring smooth production processes.

In public works, they are widely used for installing pipes and building roads, making city development more efficient and convenient. Additionally, in agriculture and forestry, excavators show their strong capabilities by easily handling soil and moving trees, greatly aiding in the management of farmlands and forests.

These examples of excavator applications highlight their versatility and efficiency, making them indispensable heavy machinery in various industries.

Popular Excavator Brands

- Caterpillar: Known for durability and performance.

- Sany: Offers cost-effective and reliable excavators.

- Volvo: Provides advanced technology and fuel efficiency.

- Hyundai: Renowned for innovation and operator comfort.

- Hitachi: Known for high-quality construction and reliability.

- Komatsu: Offers a wide range of excavators with advanced features.

Key Considerations When Choosing an Excavator

Evaluate the specific requirements of your project, including the type of work, terrain, and material handling needs.

Budget and Financial Status

Consider the total cost of ownership, including purchase price, maintenance, and operation costs.

Impact of Terrain

Select an excavator that is suited to the terrain and conditions of your work site.

Attachment Compatibility

Ensure that the excavator is compatible with the attachments you require for your tasks.

After-sales Service and Warranty Policies

Check the warranty and service options offered by the manufacturer to ensure reliable support and maintenance.

Conclusion

Excavators are essential in earthworks, construction, and many other fields, valued for their versatility and high efficiency. When choosing an excavator, you can start by looking at the types of excavators, understanding their applications, and considering related attachments. By taking these different aspects into account, you can make a well-rounded decision to ensure that the selected excavator meets the specific needs of your project, improving work efficiency and reducing costs.

FAQs

- What is the Average Lifespan of an Excavator?

- The average lifespan of an excavator can range from 7 to 10 years, depending on usage, maintenance, and operating conditions.

- How Can I Improve Fuel Efficiency for My Excavator?

- Regular maintenance, proper operation, and using fuel-efficient attachments can help improve fuel efficiency.

- In What Conditions Are Excavators Suitable for Use?

- Excavators are suitable for a variety of conditions, including construction sites, mining operations, and municipal projects, but their performance may vary based on terrain and weather.

- What Safety Considerations Should I Keep in Mind When Purchasing an Excavator?

- Ensure the excavator meets safety standards, check for safety features, and review operator training requirements to prevent accidents and ensure safe operation.