If this is your first time buying an excavator, control technology is key. If you don’t do your homework to understand the difference in control systems, you could get a machine that either doesn’t operate the way you want or will cost a lot of money to fix, be inefficient, and make your operator uncomfortable. That’s also why you hear people say, “This thing is the most comfortable piece of junk I ever sat in,” or, “I’m tired of spending money to get this thing fixed all the time.” The reason is that they ignored control technology.

Excavator control technology plays a key role in machine performance, comfort, and maintenance costs. New buyers should understand different control patterns like SAE and ISO to make the right choice. The right excavator control system can significantly impact your productivity and operational costs.

Your excavator control technology is what allows your machine to operate at its fullest possible potential. Let’s dig into the most common control systems and what makes each one unique.

1,What Are SAE Controls in Excavators?

SAE (Society of Automotive Engineers) controls are one of the most common excavator control systems. This control system has been the gold standard for a long time and is predominantly used in manual or conventional excavators.

SAE control systems use two joysticks, one for each side of the machine, which control the boom, bucket, and tracks. This control method is familiar to many operators and provides simplicity in operation. While it’s effective, it does not offer the same level of precision as more modern systems like ISO.

SAE (Society of Automotive Engineers) controls are typically found in older models of excavators. They are relatively straightforward and easy for operators to learn. However, they can be fatiguing during long days of operation because you don’t have fine control over the machine’s movements. As a first-time buyer, it’s very important to understand the trade-off between simple and less-precise control. SAE controls are still common in smaller construction operations and tasks where you don’t need highly sensitive control.

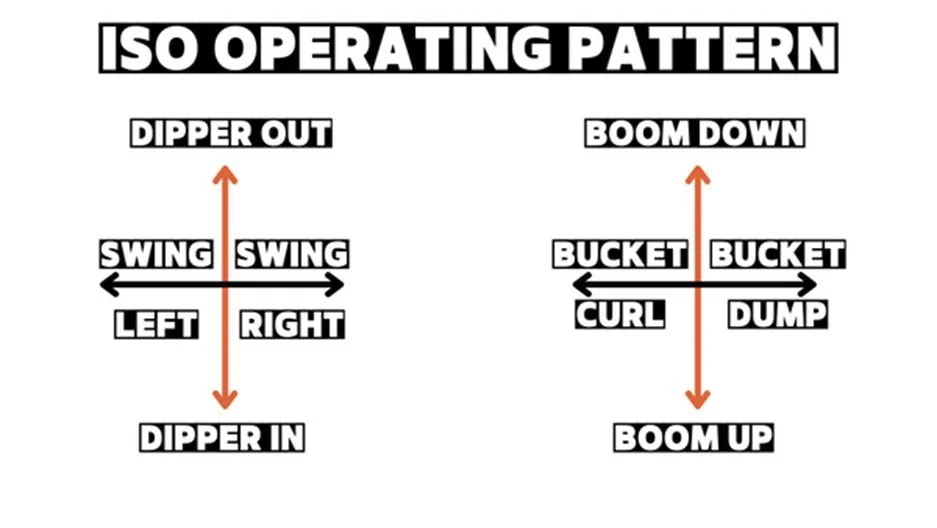

2,What Is the Excavator Control Pattern?

А excavator control pattern describes how the operator controls the movement and operation of the machine. There are several control patterns, and the type you choose can affect how easy your machine is to operate, how comfortable your operator feels running the machine, and how efficiently the machine can be operated.

Common control patterns include SAE, ISO, and even hybrid systems that combine elements of both. The choice of control pattern can affect not only the operator’s comfort but also the overall productivity of the machine. Each control pattern has its unique advantages depending on the type of work you are doing.

А excavator control pattern differs based on the machine you’re running and how the manufacturer designed the pattern into their machines. ISO and SAE represent two different philosophies in control design. ISO control patterns are better suited for modern machines doing complicated tasks and provide better precision or smoother control. SAE control patterns are still favored by many for their simplicity or ease of understanding. As a first-time buyer, think about what you’ll be doing with the machine. If you’re going to be running a machine for simpler tasks, SAE may be the way to go. If you are looking for more productivity or doing precision tasks with your machine, you’ll want the ISO control.

3,ISO Excavator Controls: What You Need to Know

ISO (International Organization for Standardization) controls are becoming the preference for most modern machines. They offer a higher degree of precision and are typically the favored control pattern for heavier duty or high-precision tasks.

ISO control systems allow for a smoother, more intuitive operation, making them ideal for complex tasks such as digging, lifting, and moving heavy materials. With ISO, the machine’s movements are more predictable, and the operator has better control over the machine’s precision.

There is a big advantage to going with ISO controls if you need to have the high precision, like with deep excavations or working in confined spaces. The joysticks operate the excavator in an ISO control pattern, and they are made to be more ergonomic. This means the operator experiences less fatigue when running the machine, plus gets a lot more movement out of the machine without exerting extra force.

If you’re a first-time buyer and considering which excavator control pattern to buy, weigh the benefit of ISO controls against the fact that you have to learn how to run them. Especially if you are not comfortable or familiar with running advanced controls, ISO might not be the best choice for you.

4,How to Understand the Excavator Control Diagram?

Excavator control diagrams are essential for understanding how an excavator’s control system works. These diagrams show you which joystick or pedals operate which cylinders on the machine, which can include the boom, bucket, and tracks.

Excavator control diagrams can seem complex at first, but they are invaluable for operators. They provide a clear overview of the machine’s various control functions, helping operators understand the layout and operation of the excavator’s systems before they begin work.

For a new machine you’re thinking about purchasing, understanding the control diagram is quite helpful. This is a comprehensive diagram of the machine with hydraulic lines, electrical connections, controls, and safety features. Having the control diagram allows you to see every component on the machine and how it interacts, which means you can troubleshoot the machine much better than looking at the pretty paint job. Typically control diagrams are included within the operator’s manual of the machine, or you can find them online with the manufacturer.

5,Exploring Different Excavator Control Patterns

Just know that there are several different excavation control patterns available to you. Each one has different characteristics, so it is essential for new buyers to realize what each one of them does. Whether you decide on SAE, ISO, or some other pattern, each has its strengths and weaknesses depending on what you’re trying to accomplish.

Control patterns can be classified based on the type of work they are suited for. SAE controls are great for basic digging and material movement, while ISO controls provide greater precision for detailed operations. Hybrid systems are gaining popularity, offering a mix of both for more versatile tasks.

For different jobs, you need different control patterns. If you are working in a quarry or on big construction sites, you would prefer an ISO control pattern because of its precision and efficiency. If you are doing simpler jobs such as general landscaping or road building, a SAE control pattern can get the job done with less ivory tower complexity. These are why you must understand this before you buy your first excavator.

6,How Do Deere Excavator Controls Compare with Other Brands?

Deere has done a fantastic job engineering their excavators to have top-notch control systems. Deere’s control technology gives you the perfect balance of precision, comfort, and durability, which is why they stand out from competitors.

Deere excavator controls are designed to optimize operator comfort while maintaining high operational efficiency. The company’s focus on ergonomic joystick designs and customizable control patterns makes it a popular choice for operators who want flexibility.

These things have a reputation for being smooth and the go-to for new excavator buyers because they are very adaptable. The reason is their system is a hybrid of the ISO and SAE controls. Its controls let you switch back and forth between ISO and SAE controls, depending on how you’re most comfortable running a machine or doing a specific type of job. That’s what makes John Deere’s controls such a perfect choice for new buyers, especially if you want that flexibility and adaptability of the controls to suit to your comfort level. Additionally, Deere’s controls are recognized for their durability, which means less likely to break or wear out.

7,Caterpillar Excavator Controls: A Closer Look

Caterpillar (CAT) makes some of the most popular and reliable excavators in the construction industry. That’s because they build them like tanks. These things stand up to the worst construction environments you can find. Caterpillar also has some of the most innovative controls for their equipment. Understanding how to control a CAT excavator is a significant factor in making an educated buying decision when you get ready to purchase your first one.

Caterpillar’s control systems focus on providing operators with a highly responsive experience. The brand offers both SAE and ISO control patterns, allowing you to select the one that best fits your operational needs. CAT controls are highly regarded for their reliability, ease of use, and precision.

The Caterpillar (CAT) excavator controls have been the go-to for years, especially in heavy-duty and high-precision types of operations. They are known for their responsive and intuitive design, which allows you to run all day without fatigue and be as productive as possible. Finally, Caterpillar provides a lot of ways for you to customize their controls to fit your comfort level or your skills. That’s why Caterpillar controls have been a favorite of practically any seasoned operator and even of the newest first-time buyer.

8,What Is the Excavator Remote Control for Toys?

It seems very basic and far away from the construction world, but those little toy excavator remote controls are a fun and excellent way for a kid to start to learn how to operate equipment.

Excavator toy remote controls typically feature simplified versions of real-world control systems. These toys provide children with a hands-on understanding of how excavators move and work, all while entertaining them.

Those little toy remote controls for toy excavators let your child operate the boom, bucket, and arm just like a pro. They use simple buttons or a joystick, helping your child develop fine motor skills and hand-eye coordination and giving them an early idea of what it’s like to run one of those sophisticated machines. It helps them decide if they like it, love it, or can’t stand it. It’s worth buying these fun, educational toys for your future construction worker.

9,Excavator Remote Control Cat: How It Works

Caterpillar makes a top-quality machine manufacturer’s version of a toy for you or the hardcore enthusiast in your life. Their cat excavator toy remote controls are the cat’s meow. With those models, you can make the boom go out and back, raise and lower the bucket, and raise and lower the arm, just like the professionals. They are as close to a real excavator control as you can get in a toy model.

The CAT remote-controlled excavator toys provide a near-real experience of excavator operation. From digging and lifting to rotating the cab, these toys help users of all ages understand the basic principles behind excavator controls.

These CAT remote control excavators are dialed in down to the smallest detail. They feature realistic joysticks that control the boom, arm, and bucket exactly as they would on a real machine. These toys are a great bridge to help children understand the real-world complexities of construction equipment control systems. This educational toy is perfect for those young ones interested in construction, engineering, or any type of work that involves running something big, powerful, and expensive.

10,How Do Excavator Control Systems Impact Operator Productivity?

Excavator controls are not just about functionality. Obviously, they’ve got to help you be able to run the machine, but they also come into play in just how fast an operator can be and efficient doing something. The ease of use, comfort, and responsiveness of the controls all play a role in how fast and efficiently you can do something.

A well-designed control system can drastically increase productivity by reducing operator fatigue and improving machine responsiveness. With the right control pattern, an operator can work more efficiently, leading to faster completion of projects and less downtime.

By having controls that you’re comfortable with on an excavator, guess what? You get to spend more time concentrating on the task at hand and less time fighting against lousy excavator control design. For example, because of the way the joysticks are set up on ISO controls, they are a much easier system to work if you have to do precision work for longer periods of time. Your body will not be as tired, your arms won’t be as sore, and your hands won’t hurt. On the other hand, with SAE controls, you have two levers to rock back and forth.

They are super simple, but you might become fatigued quicker or hurt yourself if you have to run a machine for days and weeks at a time moving those levers back and forth. The right control system also helps minimize operator mistakes, which means better work quality and greater operational productivity in the end.

11,What Are the Future Trends in Excavator Control Technology?

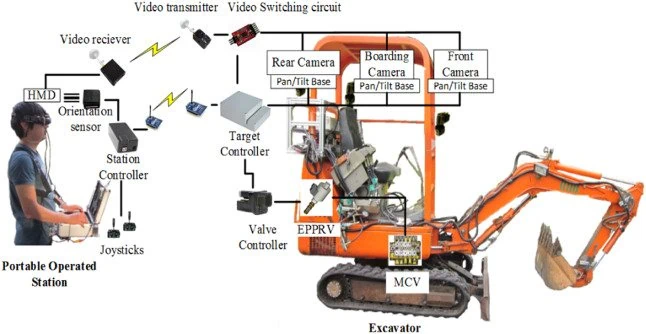

Just like with anything else, the technology for controls on an excavator will also continue to evolve. Some future trends could be automation, greater precision, safer control systems, and more intuitive control systems designed to make you faster and more productive, while at the same time reducing operator wear and tear.

Future excavator control systems will likely see further integration of AI and automation to enhance precision and reduce human error. Advanced control systems might also include virtual reality (VR) interfaces or more sophisticated telematics for remote operation.

The future of excavator control technology looks exciting. Many excavator manufacturers are pushing the envelope to make smarter, more effective machines. If you think about a Roomba that vacuums your house by itself or drones that fly themselves, you get the idea where things will likely end up. We could see automated excavators that do most of the work by themselves and require minimal human inputs. Telematics systems combined with remote controls could soon allow someone to sit in an office and run an excavator someplace else halfway around the world.

As technology advances, expect to see the systems of the future with even more customization options that let you dial your machines in to run exactly as you want for the work you do under the conditions you work in.

Summary:

Therefore, understanding the control system of an excavator is extremely relevant to new buyers, as it will directly impact the performance and productivity they can achieve with the machine. By knowing and understanding the differences between SAE, ISO, and the hybrid control patterns, buyers can make informed decisions based on their specific operational needs. The control system used will affect the comfort of the operator, the efficiency of the machine, and ultimately the time it takes to complete a project. As technology continues to advance, the future of excavator controls will likely involve more automation and even greater precision, leading to increased productivity.

Выбор правильного control system will make operations smoother, reduce fatigue, and help create a more productive work environment, making control system consideration a critical factor for anyone buying an excavator.Of course, if you have any other questions, welcome to feel free to контакт с нами. We will provide all information for your reference.