Yet the excavator safety is something that is often overlooked by many people. But what if you buy an excavator that doesn’t have any safety features built in? You could have an accident, tear something up, hurt somebody, or impair your hearing. Plus, our government is becoming more and more of a police enterprise, so you could end up with legal issues that would cost you a lot more than the potential savings that you made by purchasing an excavator that doesn’t meet safety standards. So what are the safety features you’ll want to find while shopping for excavators online?

Excavator safety is crucial for any construction or mining project. Ensuring that an excavator has the right safety features, complies with safety standards, and has been thoroughly inspected can significantly reduce risks. This guide provides essential steps for evaluating excavator safety before purchasing to keep both workers and equipment safe.

Let’s take a look at the key safety features you need to know about for your excavator and how to make sure your machine meets the required safety requirements.

1,How to Evaluate Excavator Safety Features?

When buying an excavator, the excavator safety features are critical. Are they safety features you need? We’re talking about rollover protection, excavator safety levers, alarms, and protective barriers to make sure you don’t get twisted up in them. Understanding these safety features will help you find one that has the safety you need for the operator and the site.

Excavators come with various safety features, such as ROPS (Rollover Protective Structures), safety levers, alarms, and emergency stop systems. These features are designed to protect operators from hazardous situations. When assessing an excavator, ensure that these safety elements are in good working condition.

The more excavator safety features you can get on your machine, the better. Having an emergency shut down on your machine that you can reach from where you’re sitting on a jobsite is priceless. Then you have the ROPS, the Rollover Protective Structure, built into it to protect the person operating the machine in the event of a rollover, preventing unintentional crushing. A machine that is safer will make you more productive and help you avoid some of the hazards associated with operating in the dirt.

Finally, don’t forget to read the operator’s manual for the machine. You need to know how the safety features work and how to use them correctly. Check to see if the safety features on the excavator meet or exceed the national and international standards for safety.

2,What are the Key Safety Standards for Excavators?

If you look in the manufacturer’s manual, you will see the standards. Now, every piece of heavy equipment falls under certain safety regulations with various governing bodies. These rules are put into place to protect people around, on, and near the machine. These standards will vary by region, but there are safety standards that are global that the manufacturers have to meet or exceed.

Excavator safety standards are outlined by organizations such as the Occupational Safety and Health Administration (OSHA), European Union standards (CE marking), and other international regulatory bodies. These standards help to ensure that excavators are safe to operate and maintain high operational efficiency. Always verify that the excavator complies with these safety standards before purchasing.

In the U.S., as an example, OSHA requires an excavator falls under certain safety to rules. You have to have a ROPS (Rollover Protective Structure) frame if it’s equipped with FOPS door (Falling Object Protective Structure). In Europe, it has to meet the CE certification standards, which means it meets health, safety, and environmental requirements. Again, depending on the size and use of the machine, extra safety features like an automatic stop system, pressure relief valve, or an emergency brake may be needed for certain machines. Make sure whatever you buy meets the standards because you don’t want the liability.

3,How to Inspect an Excavator for Safety Issues?

But before you buy the machine, look it over for safety. When you’re buying it is the perfect time because you can uncover problems that could be safety issues or detect future potential issues that will affect safety and performance.

To inspect an excavator for safety, focus on key areas like the structural integrity of the ROPS, the functionality of excavator safety levers, and the condition of hydraulic systems. A well-maintained excavator will have fewer risks and be more reliable. Always request a detailed inspection report from the seller and, if possible, hire a professional to inspect the machinery.

When you do your excavator safety inspection, look for any visible damage to your ROPS. Your ROPS, Rollover Protective Structure, designed to protect you in case your excavator trips over. Make sure your excavator safety lever works correctly. Push the emergency shutoff button to make sure it works like it’s supposed to. Check your hydraulic system for leaks or worn-out parts. Are the excavator operating instructions clear and easy to read to the operator? Look through the maintenance records and see if things have been taken care of. It’s somebody’s life and your wallet with this machine.

4,How to Ensure Excavator Safety During Operation?

It’s about not just what feature(s) have or doesn’t have with your excavator. It is how you use it and how you train your operator to use it.

Excavator safety during operation depends on both the operator’s experience and the safety features built into the machine. Regular maintenance, adherence to excavator operating instructions, and wearing appropriate safety gear are all crucial. Proper training can help operators avoid common mistakes that may compromise safety.

Adhere to all of the instructions for using your excavator to ensure safe operation, including using the excavator safety lever to prevent accidental activation of the machine and following the weight limits and load handling instructions. In addition, take training on excavator safety. Such training covers emergency procedures, proper lifting techniques, and how to operate safely in dangerous areas. Perform regular safety checks and equipment maintenance to minimize risks while operating your excavator.

5,What Safety Features to Look for in Used Excavators?

When you buy a подержанный экскаватор, you need to pay more attention to the safety features. Although the used machine may cost less money, having all the safety features you need to protect the operator and the machine is well worth it.

When purchasing a подержанный экскаватор, look for features such as a functional ROPS, well-maintained hydraulic systems, and effective excavator safety levers. Make sure that the machine’s safety mechanisms are intact and fully operational. Check for any previous safety violations and ensure the machine has undergone regular safety inspections.

A used excavator could be worn out, which affects its safety. For example, check the excavator safety lever to make sure it is still working and that the switch still responds. The ROPS should not have any dents or damage that would affect its usefulness in saving the operator during a rollover accident. Make sure you have all the instructions for using an excavator and that the instruction labels are clear, in good shape, and up-to-date. Finally, look at the machine’s maintenance history to ensure it gets regular safety system checks and maintenance – something that keeps you and the machine safe.

6,What is the Safety Procedure for an Excavator?

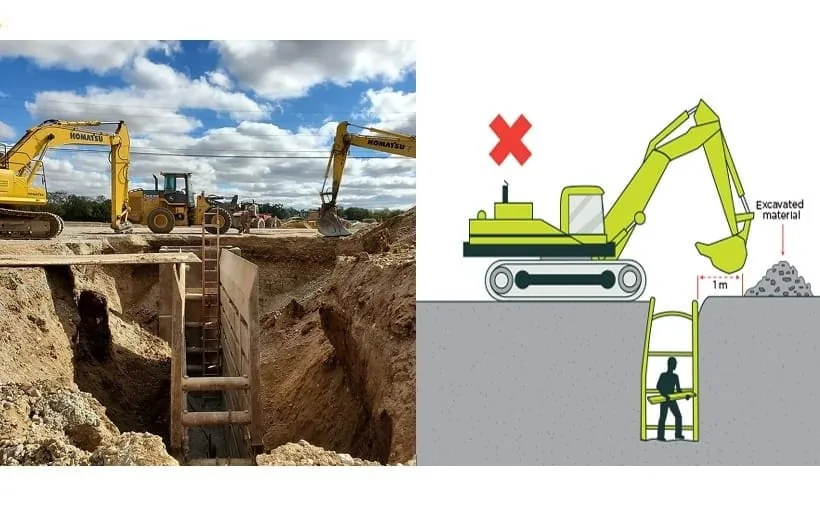

For each excavation job, you need a clear series of safety rules and procedures that prevent you from getting hurt. These are things that everybody follows so no one gets killed or hurt using the equipment and creating a safe work space.

The safety procedure for an excavator involves pre-operation checks, maintaining a safe operating environment, and following established protocols for emergencies. Operators should always review the excavator operating instructionsbefore starting work and ensure that the safety systems are functioning correctly.

Before you do any work with the machine, go through all of the safety inspection steps to make sure the excavator safety lever, ROPS, and other safety features work properly. Make sure the work area is clear. Make sure the operator gets trained in the emergency procedures. On top of that, every piece of equipment should have the emergency stop demonstrated and understood. And read and review the excavator operating instructions to know how to be safe and use the machine properly. If you use those tips, you can greatly reduce the risks of running an excavator.

7,What are the Hazards of Excavators?

Excavators are commonly used on many construction job sites. They are essential. They are also dangerous. Knowing that they are dangerous is the first step in working safely with an excavator.

Common hazards of excavators include machine rollovers, hydraulic leaks, mechanical failures, and accidents caused by poor visibility. Awareness of these hazards and proper safety precautions, including training and equipment maintenance, are key to reducing the likelihood of accidents.

The worst hazards when using excavators are rollovers. You can roll these things over very quickly, particularly if you are running them on steep ground, or the ground is unstable. Hydraulic leaks put huge oil streams where there is no power on the machine or they cause a fire in an extreme case. Another hazard comes when an operator is not properly trained. If you don’t train your operator how to find the safety lever, then why should they know how to do it? You could also have a problem if your safety systems are not time-tested, like the excavator safety lever.

Have a regular check of the safety systems, use your safety equipment, and follow your safety procedures to reduce these hazards and improve excavator safety.

8,What Precautions Should an Excavator Take?

Use these safety precautions to keep your excavator safety and running all the time. The important thing is to keep the operator safe and to keep the operator and the excavator running and working all the time.

Precautions for excavators include pre-operation checks, proper training for operators, and maintaining a clear worksite. Ensuring the excavator’s safety features, such as the excavator safety leverand ROPS, are in good condition is essential to prevent accidents.

Safety precautions will keep your excavator running and profitable. Keep the operator safe and the machine running and making money all of the time. Make sure the excavator safety lever is functional, and the ROPS is not damaged. Your operator is trained on the safety systems. Your operator is trained to spot potential accidents. Your operator is trained to be safe when things are going well, when there is an emergency, when there is a change in the process, when somebody is too close, when there is unstable ground, when they need to take a break, or when they need to quit for the day.

Work sites should be clear of unnecessary trash to avoid accidents. Have your hydraulic systems, brakes, wear surface, and other vital components in your regular maintenance program to keep your equipment making money and working for you.

9,Is it Safe to Use an Excavator?

Excavators are safe when you use them correctly. You can get hurt with them, especially when you don’t operate these machines properly. If you have a mechanical failure or an operator error, you can create an accident where somebody could get hurt, or you could get killed.

Excavators are safe when operated properly and maintained regularly. Ensuring that the excavator has all necessary safety features, and that operators are adequately trained, can minimize the risks associated with its use.

Safety when using an excavator is reliant on multiple things such as training in safety, usage, or mechanical failure as well as the use of safety equipment like the safety lever, or ROPS, on an excavator. Be sure to read the excavator operating instructions. Have your operator operate the machine safely. Keep the machine maintained. Check the safety every time you go to work with it.

10,What Safety Equipment is Needed for an Excavator?

It is not just a matter of the machine when it comes to excavator safety. Your PPE is very important. Your personal protective equipment is the key to your safety around a piece of equipment.

Safety equipment for excavator operators includes helmets, high-visibility clothing, gloves, and steel-toed boots. In addition, safety harnesses and ear protection may be required depending on the work environment.

Of course, it’s all well and good to have a ROPS (Roll-Over Protective Structure) and in certain excavators a FOPS (Falling Object Protective Structure). But the majority of operators should also wear all the necessary safety gear on the job site. These include high-visibility clothing, steel-toed boots, a hard hat (always wear a hard hat; you never know when debris might fall on you, or you might hit your head on something), and ear protection if you are in a high decibel environment. As always, the PPE will only protect you if you are wearing it. The other key to safety is regular training on the proper use of all of this equipment.

11,What are the Control Measures for Excavators?

Control measures are simply systems or protocols in place to control risks and assure you have a safe operation. What are the control measures for excavators? Where them out. A properly trained operator is a significant safety control. Proper maintenance of the machine is another safety control. Using all the safety devices on the machine, like the ROPS and the safety levers, is another control.

Control measures for excavators include operator training, regular safety checks, and the use of safety devices like excavator safety leversand emergency stop systems. Proper site planning and communication are also essential control measures.

To safely use an excavator, the operator must be trained to use the excavator safety lever and understand the emergency stop system on the machine. Well-maintained ROPS (Roll Over Protective Structure) and the hydraulic system also play a part. Properly plan your site, communicate with ground workers, and use proper operating instructions to control the operation of the excavator. If you do all these things, you will operate your machine much safer, and you’ll have fewer accidents.

12,What are the Basic Controls for Excavators?

You must be able to understand the basic controls of an excavator. You have to know how to operate the machine safely, and you have to know how to respond in an emergency. How do you perform this task? You get trained.

The basic controls for excavators include the boom, arm, bucket, and swing controls. These controls allow the operator to maneuver the excavator with precision and maintain safety throughout operation.

How do you control an excavator? The basic controls on an excavator control the boom, the arm, the bucket, and the swing. You must be able to control all those functions. They control the movement of the machine, so you have to know what you are doing. You have to learn the excavator operating instructions. Also wear the machine specific safety gear such as the worksite-specific safety gear I described earlier if you are confined or in a hazardous environment. And don’t forget the ROPS and the safety lever on the machine, they will enhance and make you safer.

Краткое содержание

Excavator safety is the most critical part of buying and operating a piece of heavy equipment. Whether it is evaluating ROPS and safety levers, or meeting safety standards, safety is the watchword and should never be circumvented. Buy a safe excavator. Operate the excavator safely. The combination of a well-maintained machine with functioning safety features and a properly trained operator will help you combat against injury, death, and destroyed equipment. Conduct your pre-operation checks. Follow the operating instructions for an excavator. PPE is a good idea. It is also a great idea to understand your machine, how it operates and how to stop it, both manually and with an emergency stop system, on the jobsite.

If you buy a machine that is designed with safety in mind and always do safety protocols, not only is the operator safe, but the chances of accidents are reduced. You will also have a more productive and efficient jobsite. Besides being a legal and moral imperative, working safely leads to the success and reliability of your excavation project in the long term.