During engineering construction, the fuel efficiency of equipment is of crucial importance. For the Volvo EC220D excavator, methods for improving fuel efficiency have important practical significance and broad development prospects. Through continuous exploration and application of these methods, not only can construction costs be reduced and economic benefits be improved, but also contributions can be made to environmental protection.

Main improving fuel efficiency methods

(1) Reducing driving resistance

During the construction process, the driving resistance of the vehicle is one of the important factors affecting fuel consumption. When the vehicle is driving on an uneven road surface, the deformation of the suspension device and tires increases, resulting in a significant increase in rolling resistance, and the fuel consumption will increase by 30% – 50%. Therefore, it is necessary to repair and maintain the construction access road well. In addition, the transmission ratio of each gear in the vehicle transmission has a great influence on fuel consumption. During construction, high-speed gear with a small transmission ratio should be selected as much as possible, which can save fuel.

(2) Increasing the engine compression ratio

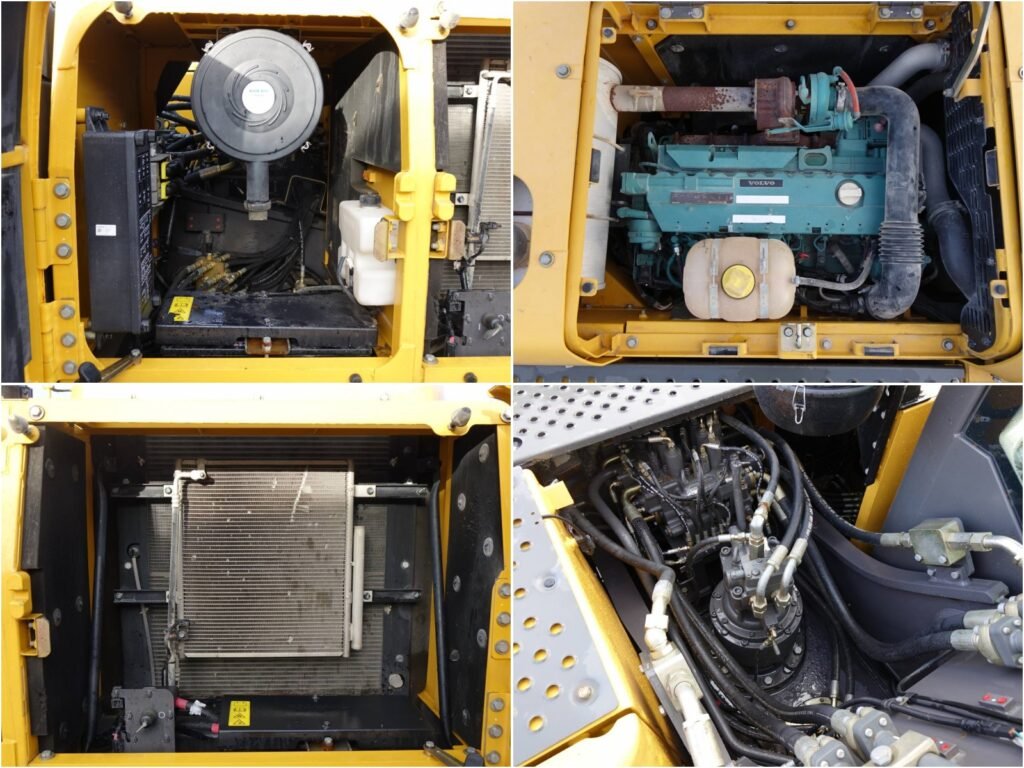

Increasing the engine compression ratio can increase the temperature and pressure at the end of compression, which is beneficial to the combustion and expansion of the mixture gas, improves the thermal efficiency of the engine, increases the effective power, and reduces fuel consumption. For example, regular maintenance and adjustment of engine parameters for the Volvo EC220D excavator can effectively increase the compression ratio and reduce fuel consumption.

(3) Calibrating the fuel supply advance angle

When the fuel supply advance angle is too large or too small, it can lead to an increase in the fuel consumption of the engine. Therefore, to ensure good performance of the engine, the fuel supply advance angle must be calibrated.

(4) Reducing the fuel consumption per unit load

Under the condition that the vehicle condition allows, increasing the load capacity of the vehicle to the rated load can not only improve the production rate but also significantly reduce the fuel consumption per unit weight. For example, when the volvo EC220D excavator is performing loading operations, reasonable control of the load weight can effectively reduce the fuel consumption per unit load and improve construction efficiency.

(5) Reasonable operating habits

1Avoid violent driving and driving on bad road sections, check for carbon deposits clean the throttle injector, and adopt the eco mode. Violent driving will lead to an increase in fuel consumption, and driving on bad road sections will increase the driving resistance of the vehicle.

2. When loading, keep the excavator at a higher position and make the truck at the same height as the working surface. When excavating, select the appropriate angle and range.

3. It is advisable to control the rotation angle within 30° – 45°. When continuously excavating, place the chassis in the forward direction, and when digging a trench, start from both sides. Reasonable control of the rotation angle can reduce unnecessary movements and reduce fuel consumption. Placing the chassis in the forward direction can improve the stability and efficiency of the operation. Starting from both sides of the trench can reduce the resistance of excavation and improve fuel efficiency.

4. Set the engine throttle at the economic gear position, select the automatic idle function, and adopt the segmented excavation method. The economic gear position can reduce the engine speed and reduce fuel consumption. The automatic idle function can automatically reduce the engine speed when the excavator is not working to save fuel. The segmented excavation method can improve the excavation efficiency and reduce fuel consumption.

| Fuel-saving Methods | Specific Measures |

|---|---|

| Reduce driving resistance | Repair and maintain the construction access road well; Select a high-speed gear with a small transmission ratio as much as possible during construction |

| Increase the engine compression ratio | Conduct regular maintenance and adjustment of engine parameters for the excavator |

| Calibrate the fuel supply advance angle | Calibrate the fuel supply advance angle to an appropriate state |

| Reduce the fuel consumption per unit load | When the vehicle condition allows, increase the load capacity of the vehicle to the rated load (for example, control the load weight reasonably during the loading operation of the excavator) |

| Reasonable operating habits | Avoid violent driving and driving on bad road sections, check for carbon deposits clean the throttle injector, and adopt the eco mode; Keep the excavator at a higher position during loading and make the truck at the same height as the working surface. Select the appropriate angle and range during excavation, control the rotation angle within 30° – 45°, place the chassis in the forward direction during continuous excavation, and start excavating from both sides when digging a trench; Set the engine throttle at the economic gear position, select the automatic idle function, and adopt the segmented excavation method |

Maintenance points

As an important part of the fuel system, the filter has a key influence on the performance and fuel efficiency of the engine. According to relevant data, when the pressure loss △P≥0.02 – 0.03MPa of the filter, the filter element should be cleaned or replaced; when the pressure loss △P≥0.01 – 0.015Mpa of the filter before the flowmeter, the filter element should also be cleaned or replaced.

Good maintenance of lubrication points can reduce equipment wear and improve operation efficiency. The lubricating grease recommended by Volvo should be selected according to the temperature. Before winter, replace the ordinary lubricating grease in the pipeline. In winter, place the grease gun and the lubricating grease bucket in the main pump room for heating, so that it will be easier to apply the lubricating grease.

The maintenance of the distribution box cannot be ignored. Engineering maintenance personnel should regularly clean the dust on the surface of the distribution box with a brush and wipe the stains on the non-live parts on the surface with a wet cotton cloth.

Resumen

The Volvo EC220D excavator has achieved an improvement in fuel efficiency through various methods. From reducing driving resistance to increasing the engine compression ratio, from calibrating the fuel supply advance angle to reducing the fuel consumption per unit load to cultivating reasonable operating habits and focusing on the maintenance and management of equipment, each link has contributed to improving fuel efficiency.

However, in practical applications, improving fuel efficiency also faces some challenges. For example, different construction environments and operation tasks have different performance requirements for excavators. How to always maintain high-efficiency fuel utilization in complex and changeable working conditions is a difficult problem. In addition, the skill level and working habits of operators will also have an impact on fuel efficiency. How to ensure that operators correctly use the equipment and fully exert its energy-saving potential is also a problem that needs to be solved.

Despite the challenges, the potential for improving the fuel efficiency of the Volvo EC220D excavator is still huge. With the continuous progress of technology, the engine performance can be further optimized, the hydraulic system can be improved, and a more intelligent control system can be developed in the future to achieve higher fuel efficiency. At the same time, strengthening the training and management of operators and improving their energy-saving awareness and operating skills will also help to fully exert the energy-saving potential of the equipment.