Operating a skid steer loader effectively is a valuable skill for everyone in construction, agriculture and landscaping industries. The skid steer is known for its versatility and compact design, ideal for working in confined spaces. However, despite its flexibility, improper operation may lead to safety hazards and reduce the machine’s productivity. Whether you’re new to skid steer driving or looking to sharpen your skills, understanding the fundamentals of skid steer operation is crucial for success.

By learning how to operate a skid steer, you can minimize risks and maximize efficiency on your job site. Mastering the skid steer controls, driving techniques and safety measures will make you a more effective operator. This guide will walk you through everything you need to know about how to operate a skid steer loader, including pre-operation checks, basic maneuvering and maintenance tips.

To operate a skid steer loaderefficiently, you need to follow essential steps like checking the machine, familiarizing yourself with skid steer controlsand mastering both basic and advanced skid steer drivingtechniques. These actions will enhance your work performance and ensure safety.

Let’s go on reading to learn key steps you need to take to operate a skid steer loader successfully.

Skid Steer Loader Startup and Inspection Process

Ensuring the safety and stability of your skid steer loader before operation is the crucial first step. A thorough startup and inspection process is vital to ensure that the loader operates correctly and avoids unexpected malfunctions during work. A well-maintained skid steer will provide better performance, safety and longevity, reducing the chances of breakdowns or costly repairs.

The startup inspection is a necessary step to ensure your skid steer loader works properly. Checking key systems like fluid levels, the hydraulic system and external components ensures smooth skid steer operations and prevents potential issues.

Before starting the skid steer loader, perform a series of checks to ensure everything is in working order. This process starts with inspecting the key fluids—hydraulic oil, fuel and coolant. It’s essential to check that these fluids are at the correct levels and that there are no leaks. Leaking fluids can lead to performance issues or even engine failure if left unchecked. Hydraulic fluid is particularly important, as it powers the loader’s lifting and movement functions. If the hydraulic system is not properly lubricated or has low fluid levels, you may experience difficulty operating a skid steeror using attachments.

Tire pressure: check the tire pressure to ensure that the loader has optimal stability and traction. Under-inflated or over-inflated tires can affect the loader’s maneuverability, leading to uneven wear or poor performance on uneven ground. Regularly check the tires for damage, punctures or excessive wear. Ensure that the treads are in good condition and that the tires are properly inflated according to the manufacturer’s recommendations.

Battery:The condition of the battery is another crucial aspect of the pre-startup inspection. A dead or weak battery can prevent the loader from starting or cause intermittent electrical issues during skid steer operations. Check the battery terminals for corrosion or dirt and clean them if necessary. Also, ensure that the battery charge is at an appropriate level to guarantee reliable operation. If the battery shows signs of wear or aging, it’s wise to replace it before starting work.

Perational panel and dashboard: You should also inspect the operational panel and dashboard for any warning lights. Warning lights indicate that a system may be malfunctioning, which could affect the skid steer operationsor safety. If any warning lights are illuminated, take the time to address the issue before starting the engine. It’s better to resolve potential issues early rather than risk operating the skid steerwith underlying problems.

Satrt the engine:Once all the checks are complete, it’s time to start the engine. Begin by turning the ignition switch to the “on” position. Allow the engine to warm up for a few moments, letting the engine speed stabilize. Never rush into operating a skid steerimmediately after turning on the engine, as doing so can put unnecessary stress on the engine components. Once the engine is stable, engage the controls and ensure that all systems, including the steering, brakes and hydraulics, are functioning correctly.

By conducting these essential startup checks, you ensure that the skid steer loaderis safe to operate and ready for work. These steps help you avoid problems that could arise during the operation, making your workflow more efficient. Regularly performing startup and inspection routines also helps in maintaining the longevity of the equipment, preventing major repairs and improving the overall safety of the job site.

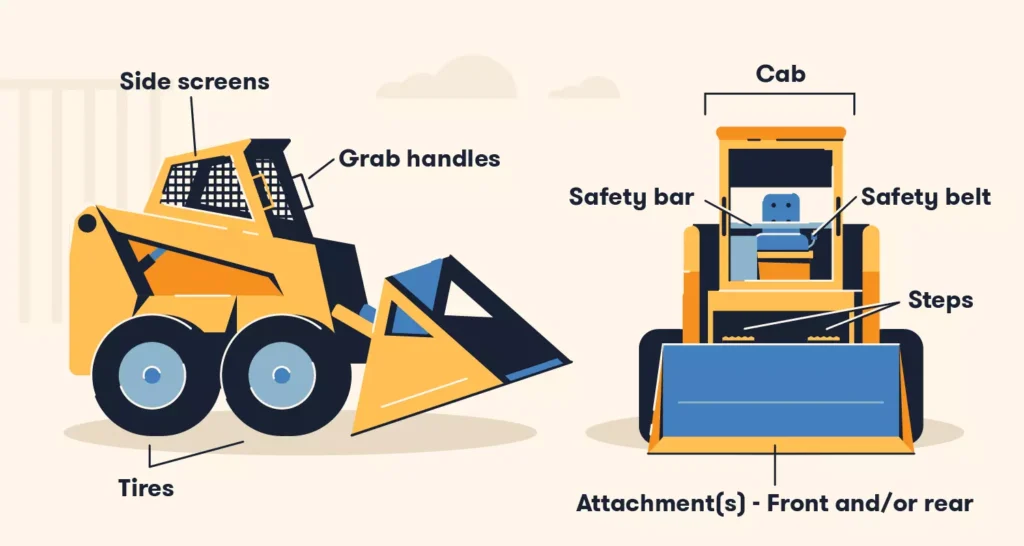

Understanding Skid Steer Controls: The Key to Smooth Operation

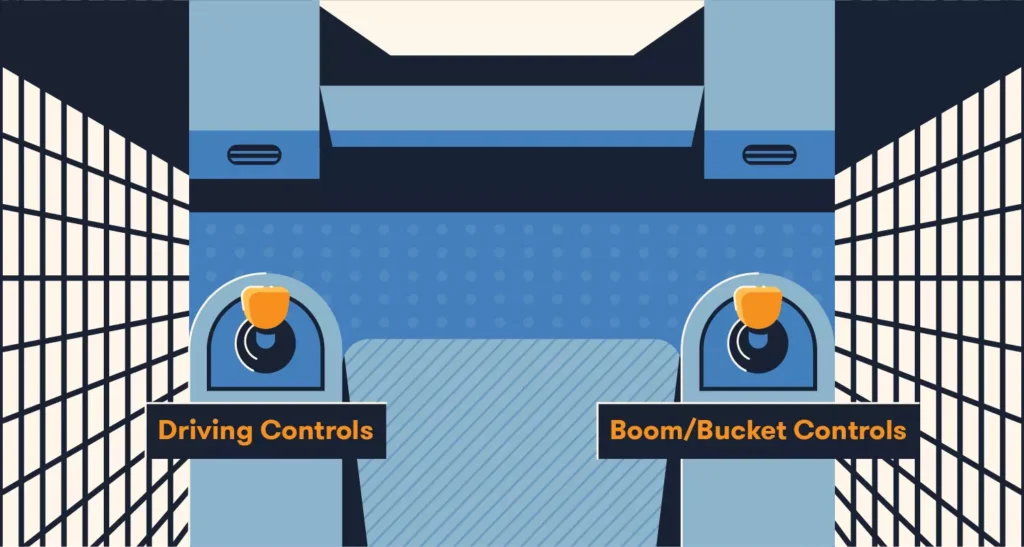

Skid steer loadershave a unique set of controls that require practice to master. Familiarizing yourself with these controls is crucial to efficient skid steer operation. The basic controls are typically divided into two joysticks, each responsible for different movements of the loader. Learning how to operate a skid steerinvolves becoming comfortable with both basic and advanced control systems.

Skid steer controlsare essential for operating the machineeffectively. By understanding the functions of the joysticks, auxiliary controls and other systems, you can improve both your safety and performance on the job site.

- Joystick Control: Each joystick controls the movement of one set of wheels (left or right) on the skid steer. Pushing the left joystick forward moves the left wheels, while pulling it backward moves them in reverse. Similarly, the right joystick controls the right wheels.

- Combined Movements: When both joysticks are pushed forward or pulled back simultaneously, the skid steer moves forward or backward. To turn, move one joystick forward while pulling the other back. This type of differential steering gives the skid steer its maneuverability in tight spaces.

- Auxiliary Controls: These controls allow you to adjust the loader’s attachments, such as the bucket, forks or snow plow. Learn how to operate a skid steer with these attachments to enhance your skid steer operations, depending on the job at hand.

Understanding these controls is essential for efficient and safe skid steer driving, especially when working in tight or congested spaces.

Basic Skid Steer Driving Techniques: Mastering Movement and Maneuvering

One of the key benefits of a skid steer loaderis its ability to move quickly and efficiently in tight spaces. Whether you’re on a construction site, landscaping job or farming task, learning how to operate a skid steerand use its maneuvering capabilities is essential for optimizing your workflow.

Mastering basic skid steer drivingtechniques, such as using smooth movements and steering carefully, will improve your speed, accuracy and safety on the job site.

- Starting and Stopping: To begin, gently push both joysticks forward to move the skid steer. To stop, pull the joysticks back to neutral. Always use gradual movements to avoid sudden jerks, which can cause instability.

- Turning and Pivoting: The skid steer can rotate on its axis due to the differential steering mechanism. To turn, simply push one joystick forward while pulling the other back. This allows the skid steer to rotate in tight spaces without requiring large turns.

- Navigating Obstacles: When driving through rough terrain or near obstacles, take it slow and steady. Always be aware of your surroundings and avoid sudden accelerations or sharp turns to prevent tipping or damage to the machine.

By mastering these basic driving skills, you can operate a skid steer loader with ease and maximize its efficiency on the job site.

Advanced Skid Steer Operations: Getting the Most Out of Your Loader

Once you’ve mastered basic skid steer operation, it’s time to explore more advanced techniques that will enhance your productivity. Skid steer loadersare designed to handle a wide variety of attachments and tasks, making them a great tool for complex jobs. Learning to operate skid steer loaderswith attachments such as buckets, forks or grapples can significantly improve your efficiency and the quality of your work.

Advanced skid steer operations involve using attachments and performing more complex tasks. By learning to efficiently operate skid steer loaders with different attachments, you can tackle a broader range of jobs.

- Bucket Operation: Use the bucket for digging, lifting and transporting materials. Tilt the bucket forward to scoop up dirt or debris and use the loader’s lifting capabilities to move the material to a desired location.

- Forks and Grapples: Attachments like forks or grapples are useful for lifting heavy materials such as pallets, logs or scrap. When using forks, always maintain a low and balanced center of gravity to prevent tipping.

- Specialized Tasks: Depending on your job, you may use other attachments like a snowplow, broom or auger. Each attachment has its own specific operation method and understanding how to operate a skid steer with these tools will increase your work efficiency.

Learning advanced operations and techniques will make you a more versatile and productive operator, allowing you to tackle a wide range of tasks with confidence.

Parking and Securing the Skid Steer Loader

When it’s time to park the skid steer loader, you must follow the correct procedures to ensure its safety and longevity. Proper parking ensures that the machine is secure and ready for the next use.

Always park the skid steer loaderon a flat surface, engage the parking brake and lower the arms and attachments to the ground. Turning off the engine is also essential to avoid unnecessary wear and ensure the machine is safely parked.

- Flat, Stable Surface: When parking your skid steer, it’s crucial to find a flat, stable surface. Parking on an incline can lead to the machine rolling, especially if the parking brake is not engaged properly. If you must park on an incline, position the heaviest part of the loader facing uphill to avoid rolling.

- Engage the Parking Brake: Always engage the parking brake when parking your skid steer loader. This prevents the machine from rolling, even if it’s on a slight incline. Failing to engage the parking brake can lead to the machine moving unexpectedly, posing safety risks to operators and nearby workers.

- Lower the Arms and Attachments: Always lower the loader arms and any attached tools to the ground. This helps stabilize the skid steer and minimizes wear on the hydraulic systems. It also ensures that attachments won’t get damaged or put unnecessary stress on the loader’s lifting mechanisms.

- Turn Off the Engine: Turning off the engine is essential when parking the loader for an extended period. This helps conserve battery life and prevents unnecessary wear on the engine. Additionally, it reduces the risk of accidental startup, ensuring safety for anyone nearby.

Properly parking your skid steer loaderwill prolong its lifespan and ensure it is secure when not in use.

Routine Maintenance: Keeping Your Skid Steer in Optimal Condition

To ensure your skid steer loaderruns smoothly for years, regular maintenance is essential. Skid steer operationsare demanding and taking care of the machine will prevent costly repairs and improve its overall efficiency.

Routine maintenance includes checking oil levels, inspecting tires and cleaning filters. Keeping your skid steer loaderwell-maintained will enhance its longevity and reduce downtime.

- Oil Changes: Regularly check the oil and replace it according to the manufacturer’s schedule. Low oil levels or old oil can cause engine damage and reduced performance.

- Tire Inspections: Inspect the tires for wear and tear. Tires with proper air pressure and tread depth ensure better traction, reducing the risk of slipping or getting stuck during skid steer operations.

- Hydraulic Fluid and Filters: Check and replace hydraulic fluid and filters regularly to ensure the loader’s lifting capabilities remain strong.

- Cleaning: Clean the machine regularly to prevent dirt and debris from causing damage to the engine, hydraulics or other critical components.

Proper maintenance is vital for the longevity and performance of your skid steer loader, helping you get the most out of every skid steer operation.

Common Mistakes When Operating a Skid Steer Loader

Operating a skid steer loader can seem straightforward, but even experienced operators can make mistakes that affect machine performance, safety, and efficiency. Understanding these common errors can help prevent costly repairs, downtime, and accidents. By avoiding these mistakes, you can ensure that your skid steer operations are smooth and productive.

Common mistakes in skid steer driving can lead to equipment damage, safety hazards, or inefficient operation. Proper training and awareness can help prevent errors such as overloading, improper steering, and poor maintenance practices.

Here are some of the most common mistakes made during skid steer operations and how to avoid them:

- Overloading the Skid Steer Loader: One of the most frequent mistakes is overloading the loader. When the machine is loaded beyond its capacity, it can cause strain on the hydraulic system, engine, and tires. This not only leads to inefficient operation but also increases the risk of mechanical failure. Always check the loader’s weight capacity and never exceed it. Load materials evenly to maintain balance and prevent tipping.

- Improper Steering and Control: Another common mistake is improper steering, especially when operating on uneven terrain. Sudden, sharp turns can cause the skid steer loader to tip over or damage the tires. Practice smooth, controlled movements when turning and use both steering levers correctly to ensure balanced turns. Avoid jerky motions, as they can damage the loader’s components and reduce the longevity of the equipment.

- Not Checking the Attachments Properly: Before using any attachments, ensure they are securely connected to the loader. Failing to check the attachment can result in the loader’s instability or cause the attachment to fall off during operation. Always inspect and lock attachments properly before use. Attachments should be compatible with the loader and fit securely to ensure smooth and safe operation.

- Neglecting Proper Maintenance: Skipping regular maintenance is another common error. Regularly cleaning and inspecting the skid steer loader helps prevent issues such as overheating, hydraulic fluid leaks, and tire wear. A well-maintained loader runs more efficiently and lasts longer. Be sure to follow the manufacturer’s maintenance schedule and replace parts when necessary to avoid unexpected breakdowns.

- Operating Too Quickly: Rushing through tasks or operating the loader too quickly can lead to mistakes, including tipping over, losing control, or causing damage to the machine. It’s essential to operate the loader at a safe speed and take your time to avoid accidents. Always adjust your speed based on the terrain and the load you are carrying.

- Not Using the Loader’s Full Range of Functions: Many operators fail to take full advantage of the loader’s capabilities, either by neglecting certain functions or not using them properly. Skid steer loaders come equipped with various features, such as adjustable arms and different speed settings. Familiarize yourself with all the loader’s functions and use them to increase efficiency and improve the quality of your work.

By avoiding these common mistakes, you can maximize the efficiency and safety of your skid steer operations. Proper training, awareness, and regular maintenance will help keep your loader running at peak performance, reducing the risk of accidents and ensuring that your equipment serves you well for years to come.

Abschluss

Mastering how to operate a skid steer requires practice, knowledge of controls and adherence to safety and maintenance protocols. By understanding skid steer operations, practicing proper driving techniques and maintaining the machine, you can ensure the loader’s efficiency and safety, enhancing your productivity and ensuring long-term success. We are leading supplier of used construction machinery, if you need any used skid steer loaders, please contact with us.