The Caterpillar 320D excavator is a widely used piece of heavy machinery in large earthwork projects, mining operations, and infrastructure construction. Weighing between 21 to 24 tons, it boasts powerful digging and traction capabilities, enabling it to handle heavy tasks efficiently. However, due to its large size and immense operating power, safety precautions are crucial when operating this machine. This guide covers the key safety measures for operating the Caterpillar 320D excavator.

1. Excavator operation safety: preparation before operation

1.1 Understanding Site Conditions

Before operating the Caterpillar 320D, it is essential to thoroughly understand the working site conditions. Discuss with relevant personnel the height and depth of the fill and excavation areas. In sites where the fill height is significant, extra caution is needed to avoid landslides due to loose soil. Additionally, assess the slope stability, as it directly affects operational safety. You should also check the height of nearby power lines, ensuring a safe distance between the excavator and the wires to prevent accidents.

1.2 Handling Special Terrain

In rocky soil environments, large rocks can damage the excavator’s bucket and tracks. Before excavation, it may be necessary to blast larger rocks into smaller pieces for easier handling. In the frozen ground, the difficulty of excavation increases. It’s recommended to thaw the frozen soil using heating methods or defrosting agents before digging. During excavation, monitor the soil conditions to avoid landslides caused by sudden thawing, and ensure the excavator’s tracks are equipped with anti-slip measures to ensure safe movement on frozen ground.

1.3 Equipment Inspection and Maintenance

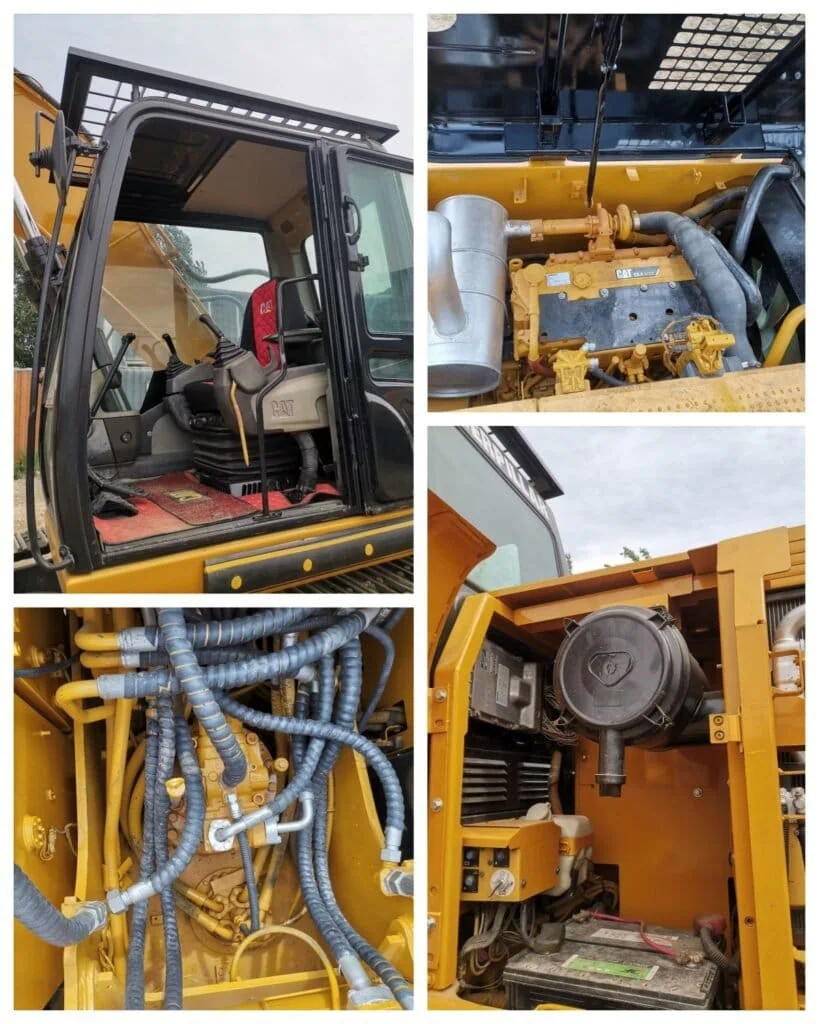

Before operating the Caterpillar 320D, a thorough inspection and maintenance check is essential to ensure the machine is in good working condition. First, ensure the fuel level is sufficient. The Caterpillar 320D uses diesel fuel, and depending on the workload, fuel consumption may vary. Ensure the fuel tank is full before starting operations to avoid interruptions. Additionally, check the oil levels, as adequate lubrication is critical for the proper functioning of the engine and various components.

2. Excavator Operation Safety: During Operation

2.1 Proper Excavation Techniques

When operating the Caterpillar 320D, ensure that the digging depth is within a reasonable range. Based on operational experience, it’s recommended that each excavation load should not exceed two-thirds of the bucket’s capacity. For instance, the Caterpillar 320D has a bucket capacity of 1 cubic meter, so the ideal excavation depth per scoop is around 0.67 cubic meters. This prevents damage to the machine and reduces the risk of tipping. The boom should be lifted smoothly to avoid excessive impact force on the machine. When lowering the bucket, control the speed and angle to avoid damaging the tracks and chassis. Statistics show that improper lifting or lowering of the bucket accounts for around 15% of excavator-related mechanical damage incidents.

2.2 Personnel Coordination Safety

When co-workers are within the excavator’s swing radius, the operator must strictly adhere to safety protocols. First, halt all swing movements and lock the swing mechanism to ensure the excavator is stable. This precaution prevents accidental swings that could harm those working nearby. It is essential to establish clear communication signals or gestures between the operator and ground personnel, especially during tasks like leveling, finishing, or slope shaping. It’s estimated that around 10% of excavator-related accidents are due to poor coordination between team members.

2.3 Safe Loading Techniques

When loading material onto a truck, ensure the truck is fully stopped and the driver has exited the cabin before rotating the excavator’s bucket. Avoid swinging the bucket over the top of the truck’s cabin to minimize risk. Keep the bucket low during loading, but be cautious not to collide with any part of the truck. Improper loading techniques can lead to vehicle damage and personnel injury, so careful operation is crucial.

2.4 Safety in Special Operations

When performing dragline operations, prevent overloading by ensuring the bucket is not overloaded. While digging trenches or channels, maintain a safe distance from the slope edge, generally no less than 2 meters, depending on the depth, slope, and soil type. During backhoe operations, ensure the arm is steady before starting to dig, and avoid abrupt or excessive movements when retracting or extending the boom. Operators must be familiar with the safety protocols for each specific operation to prevent

Conclusion

The Caterpillar 320D excavator is a high-performance machine, but its safe operation is critical. By understanding site conditions, inspecting the equipment, following proper operating procedures, and ensuring team coordination, the risk of accidents can be significantly reduced, and work efficiency improved. Safety should always be a top priority to ensure a smooth and productive operation.