About Function of excavator, If you’re in the market to buy an excavator, it can feel overwhelming with so many options. How can you be sure the machine you choose will work for you? To decide on the right machine, you need to understand what an excavator does. Here are five of the primary functions of an excavator.

The function of excavator depends heavily on its design and capabilities. From digging and lifting to rotating and hydraulic operations, understanding these features can help you select the perfect excavator for your job site. In this article, we will explore the core function of excavator and the most important factors to consider when buying.

Now that we looked at the basic function of excavator let’s look at how engine power and the hydraulic system work together to make all of those functions go round.

1,What Are the Key Function of Excavator?

That’s the bottom line: Excavators are powerful machines built to handle an amazing variety of construction and earthmoving tasks. As we’ve shown, excavators dig, lift, and rotate. Each function is used for different types of work environments. To choose the right excavator, you want to know what each function of excavator and feature does so you can select the machine that meets your project requirements.

What an excavator does is determined by its hydraulic system. The hydraulic system runs the digging arm, bucket and any other attachments you have. With a good working hydraulic system, an excavator can do everything from digging a trench to breaking concrete and even lifting heavy materials.

You see, an excavator is not a simple digging machine. It’s actually a versatile tool capable of many functions besides digging. An excavator can help lift something, dig a hole, clean a ditch, or even move material from place to place. Here are some of the primary function of excavator:

| Function | Description | Best Use Case |

| Digging | Used to excavate soil and materials from the ground. | Trenching, site preparation, foundation work. |

| Lifting | Lifts heavy materials like pipes, steel beams, etc. | Transporting materials to and from construction sites. |

| Rotating | Allows the machine to rotate its boom for accurate work. | Excavation work in tight spaces, demolition tasks. |

| Breaking (with attachment) | Attachments like hammers or crushers break hard surfaces. | Demolition of concrete, breaking asphalt, or rocks. |

| Grading | Smoothing or leveling the ground after digging. | Final grading for landscaping or road preparation. |

By understanding these function of excavator, you can select the right excavator for your needs. Are you going to do a lot of digging, need a little more digging depth, or need to lift things with the excavator? Maybe you need multi-functional attachments that can run off the same machine.

2,How Does the Engine Affect Excavator Performance?

The engine is the heart of an excavator, and its performance is directly related to the engine’s performance. The function of excavator is highly dependent on the power, fuel efficiency, and stamina of the engine. An engine you choose can contribute to productivity and the long-life of your excavator if it’s matched properly to the work environment.

The more power, the more digging force, faster cycle times, and better fuel economy. By understanding the function of the engine in the work an excavator performs, you can make sure it has the muscle to work in the demanding conditions of your job site.

When you’re buying an excavator, you want to look at the horsepower output and fuel economy of that engine. Here’s how the engine affects how an excavator can work for you:

| Engine Type | Power Output | Fuel Efficiency | Function Impact |

| Diesel | 100-400 hp | Moderate | Suitable for heavy lifting and continuous work. |

| Electric (Hybrid) | 50-250 hp | High | Best for quiet, low-emission work environments. |

| Hybrid (Diesel + Electric) | 150-500 hp | High | Combines the power of diesel with the efficiency of electric systems. |

| Low-Emission Diesel | 100-350 hp | Moderate to High | Ideal for environmentally-sensitive areas. |

Engine type goes a long way in determining the power and efficiency of that excavator. The engine can make a big difference in how well the excavator digs, lifts, and even breaks things.

3,What Role Does the Hydraulic System Play in Excavator Functionality?

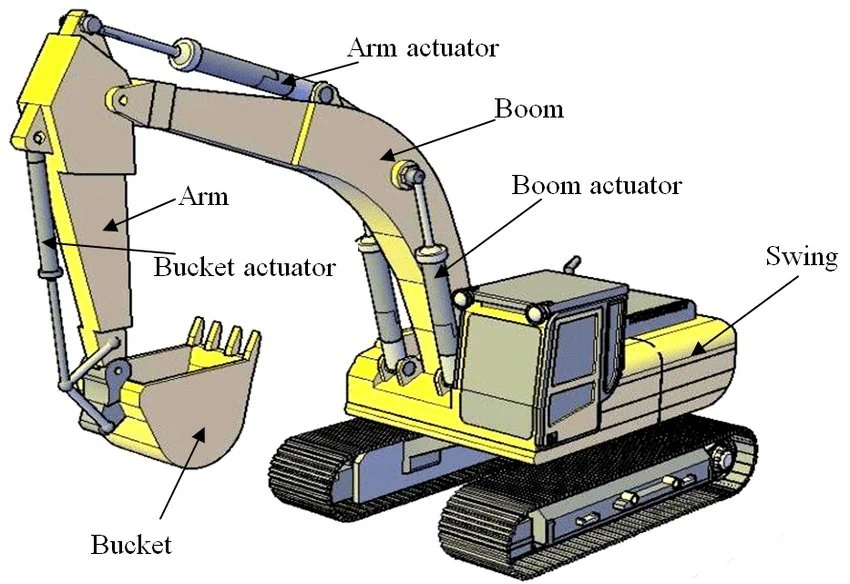

Hydraulics are the heart of an excavator’s function. The function of excavator depends on its hydraulics to move the arm, the body, and attachments. The hydraulics are what make the excavator move.

That is what allows the excavator to move so smoothly and under perfect control. A high-performance hydraulic system can mean the difference between the machine barely working or the machine working all the time for you.

Your excavator’s hydraulic system is what allows you to use your arm, boom, and bucket smoothly and with exact control. A high-performance hydraulic system is what allows you to do amazing tasks with little effort and endless power:

| Hydraulic System Component | Function | Impact on Excavator Function |

| Hydraulic Pump | Powers the machine’s hydraulic system. | Determines the strength and speed of movements. |

| Hydraulic Cylinders | Controls the movement of the boom, arm, and bucket. | Affects the precision of digging, lifting, and rotation. |

| Hydraulic Oil Reservoir | Stores and supplies hydraulic fluid to the system. | Affects the system’s efficiency and smooth operation. |

| Filters | Prevent dirt and debris from damaging the hydraulic system. | Ensures hydraulic fluid remains clean, prolonging system life. |

Only when you understand the importance of each part of a hydraulic system can you know how efficient and reliable that excavator will be at digging, lifting, or performing tasks like breaking concrete or moving a heavy load.

4,What Should Buyers Consider Regarding Excavator Maintenance and Longevity?

With a hydraulic system made from a variety of components and hoses, you’ll want to make sure you have a maintenance plan in place. You have a beautiful machine that will serve your job sites for years, and it operates smoothly and efficiently as long as you maintain it.

Your maintenance and care of your excavator will determine how well it works and how long it lasts. A well-maintained machine runs better, has fewer breakdowns, and lasts much longer. Remember to maintain and service the engine, hydraulic system, and undercarriage according to the schedule in the owner’s manual.

Here are the key maintenance factors that affect the function of excavator over time:

| Maintenance Component | Maintenance Frequency | Function Impact |

| Engine Oil & Filters | Every 250-500 hours | Ensures smooth engine operation and efficiency. |

| Hydraulic Fluid & Filters | Every 500 hours | Keeps the hydraulic system efficient and prevents damage. |

| Undercarriage (Tracks) | Every 200-400 hours | Extends track life and maintains smooth operation. |

| Bucket Teeth & Attachments | As needed based on wear | Ensures effective digging, lifting, and breaking. |

Be maintenance-minded, and your machine will operate longer, digging and performing with a hydraulic thumb more effectively and efficiently.

5,How Does the Operator’s Comfort Impact Excavator Efficiency?

Operators who are comfortable will operate the machine more efficiently. The function of excavator goes beyond just the machine’s capabilities. It also encompasses how easy it is for the operator to use the equipment. The comfort of the operator should be taken into account — and into the cab — because a comfortable cab design can make a significant difference in safety and productivity.

Most operators can run slower. So it doesn’t make any difference if you have them running at 135%. They will run at that speed all day. But as a professional excavating contractor, you don’t want your guys working at 135% all the time. You want them at 65-75%. You can’t get them to do that, so you can only run them slower.

He will run slower. It doesn’t matter if you have them running at 135%. They’ll run at that speed all day long, no sweat. As a professional excavating contractor, I don’t want my guys running at 135%. I want them running at 65-75%. I can’t get them to do that, so I can only run them slower.

| Feature | Function Impact |

| Seat Design | Reduces operator fatigue and increases comfort. |

| Control System | Easy-to-use controls lead to more precise operations. |

| Visibility | Improves safety and accuracy in tasks. |

| Climate Control | Ensures the operator remains focused and comfortable. |

Comfortable operators will be able to perform the function of excavator more effectively, improving overall performance and reducing downtime.

6,How Do Excavator Attachments Affect Versatility?

Attachments can significantly change the function of excavator. The correct attachment can increase the excavator’s flexibility, allowing it to do more jobs with less hassle. Buyers need to select the correct attachments for their work environment based on the tasks they need the attachments to perform.

These attachments turn the excavator into a multi-functional tool. By knowing and respecting these attachments, buyers can feel free to customize their excavator to meet the exact needs of their job site.

Excavators can be fitted with various attachments that enhance their functionality for different types of work. Here’s a look at some common attachments:

| Attachment | Function | Common Use Case |

| Bucket | Used for digging and scooping material. | Excavation, trenching, material handling. |

| Hammer | Breaks up concrete, rock, or asphalt. | Demolition work, rock breaking. |

| Grapple | Used for grabbing and lifting materials. | Sorting materials, lifting debris. |

| Auger | Drills holes into the ground. | Post hole digging, foundation preparation. |

Attachments can make your excavator more versatile, allowing it to perform a wide range of tasks, thereby improving the return on investment.

7,How Many Types of Excavators Are There?

There are different types of excavators designed for specific tasks. Understanding the types and the task they were designed for will help you to pick the best machine for your project. From compact mini-excavators to enormous mining excavators, each type has its strengths and weaknesses.

So, how do you know which one to choose? First, consider what you want the excavator to do and then compare these to the different kinds of excavators available. If you need to dig in a small space, you don’t want a large backhoe; it just won’t work. On the other hand, if you want to dig a hole to build a house, don’t try to do it with a small backhoe. It will take you forever and be a tremendous amount of work.

Here are the most common types of excavators and their main function of excavator:

| Type of Excavator | Function | Best Use Case |

| Crawler Excavator | Offers stability and is used for rough terrains. | Heavy-duty work in construction, mining, and demolition. |

| Wheeled Excavator | More mobile and can move faster. | Urban construction projects with stable terrain. |

| Mini Excavator | Small and compact for tight spaces. | Residential construction, landscaping, and small site work. |

| Long Reach Excavator | Has an extended arm for deep digging and long reach. | Dredging, trenching, and working in deep areas. |

Choosing the right type of excavator depends on the specific function of excavator you need. Each type offers unique capabilities that cater to different types of jobs.

8,How to Evaluate the Durability of an Excavator?

Examining the durability of an excavator is crucial to ensuring the best return on your investment for the longest time. After all, excavators work in a harsh environment, so understanding their life expectancy and what makes them last could save you on expensive repairs and downtime.

The durability of an excavator depends on factors like the engine quality, your maintenance practices, and the conditions you run your equipment in every day. With proper care and attention, you might be able to keep a machine for many years, while neglect can cut the life of a machine significantly.

When assessing an excavator’s durability, several key aspects must be considered:

| Factor | Impact on Durability |

| Engine Quality | High-quality engines last longer and are more reliable. |

| Maintenance History | Regular maintenance ensures a longer lifespan. |

| Operating Conditions | Harsh conditions can accelerate wear and tear. |

| Undercarriage Condition | The undercarriage is vital for stability and longevity. |

A well-maintained excavator can offer several years of service, but its durability is heavily influenced by how it’s cared for and the environments in which it operates. Regular inspections, proper lubrication, and addressing issues immediately are key to maintaining an excavator’s durability.

9,How to Optimize Excavator Functionality for Specific Tasks?

Each job site requires different functionality from an excavator. By using your attachments to customize your excavator, change the settings and tune your machine to your job site specifically for the best performance.

Excavators can do a lot of different things, but to get them to do those things, you have to optimize their functions. That means using the right attachments and settings depending on what your project requires, whether it’s digging, grading, or lifting heavy material.

Here’s how you can optimize the function of excavator for specific tasks:

| Task | Recommended Attachment / Adjustment | Benefit |

| Digging and Excavating | Bucket or Grapple | Ensures efficient digging and material handling. |

| Demolition | Hydraulic Hammer | Breaks concrete and rock, optimizing time and labor. |

| Trenching | Long Reach Excavator or Auger | Provides deeper and more precise trenching. |

| Grading and Leveling | Tiltrotator or Grading Bucket | Improves the accuracy and speed of grading. |

By picking the proper attachment and dialing in the settings on your excavator, you can maximize the machine’s function to meet exactly what you need to do on the job site, ultimately working more efficiently and with less downtime.

Also, if you want to know more information about types of excavator,crawler excavator,brands of excavators,excavator working,parts of an excavator,hydraulic system in excavator,excavator types and sizes,excavation machine name,excavator types of buckets,excavator operator qualifications,function of excavator in construction,construction excavator,what is an excavator,what do excavators do,what is a excavator used for,what does an excavator do,what are excavators used for,what does an excavator look like,functions of excavator and function of excavator in construction, please feel free to contact with us.

PS: Why Should you choose used excavator from us?

Source Advantages. we are leading supplier of all kinds used construction machinery in China, we can offer any brand and models of used construction machines available in China. We have what you need, we can provide one-stop shopping of used wheel loaders.

Quality advantages. we are quite professional in used construction machinery market. We have professional engineers to test the used machine to ensure that each machine is in good condition, there will be no inferior and fake machines, to ensure that customers receive the machine can be directly used to work.

Price advantage. We guarantee that our prices are the best for machines of the same quality. The machines we offer are of the best quality for the same price.

Service advantages. We provide 7X24 online service, any problems or question, you can contact directly. All questions will be reply in the first place.

Summary

An excavator does so much more than dig a hole. You can use an excavator to lift heavy loads, break concrete, grade a yard, and more. Knowing what an excavator does, how it uses its hydraulic system, the type of engine it has, what attachments it can use, and how comfortable the operator is, plays a significant role in choosing the right excavator for your needs. By knowing those things, how to use and select attachments, and what type of machine is best suited for your job, you can use your machine as effectively as possible and have it be as productive as possible for as long as possible.

Knowing what an excavator does helps you make the right purchasing decision. Then choose the machine you need, whether it’s for digging, lifting, or breaking, and get the best results for your project.